Introduction to the Working Principle of Backwash Filters

A backwash filter is a precision device designed to directly intercept impurities in water using a filter screen, removing suspended solids, particulate matter, and reducing turbidity. It purifies water quality, minimizes the formation of scale, bacteria, algae, and corrosion within the system, thereby protecting other equipment and ensuring normal operation. Water enters the self-cleaning filter body through the inlet. Equipped with intelligent control systems (PLC or PAC), the device automatically detects the degree of impurity accumulation and triggers the discharge valve to initiate automatic waste expulsion.

Environmental and Economic Benefits

Fully automatic backwash filters enable industrial wastewater to meet national discharge standards, effectively protecting the environment. Additionally, treated wastewater can be recycled to meet reuse standards, addressing both pollution challenges and reducing operational costs through resource recovery.

Working Principle

-

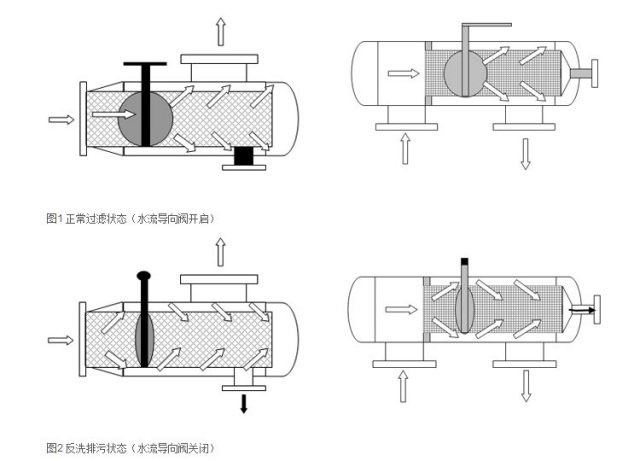

Filtration Process:

-

Water enters through the inlet and first passes through a coarse filter screen to remove larger particles.

-

It then flows through a fine filter screen. During filtration, contaminants gradually accumulate on the inner surface of the fine screen, forming a "filter cake layer."

-

This accumulation creates a pressure differential between the inner and outer sides of the fine filter screen.

-

-

Automatic Cleaning Cycle:

-

When the pressure differential reaches a preset threshold, the automatic cleaning process begins without interrupting water flow.

-

The cleaning valve opens, causing a sharp pressure drop in the cleaning chamber and suction device.

-

A pressure difference between the filter cylinder and the suction pipe generates a vacuum through the suction nozzle, initiating a waste discharge action.

-

Simultaneously, an electric motor drives the suction pipe to perform a combined axial and helical motion, thoroughly cleaning the entire inner surface of the filter screen.

-

The entire cleaning process completes within seconds. Afterward, the discharge valve closes, and the filter prepares for the next cycle.

-